Toughened glass in practice — properties, behaviour and appropriate use cases

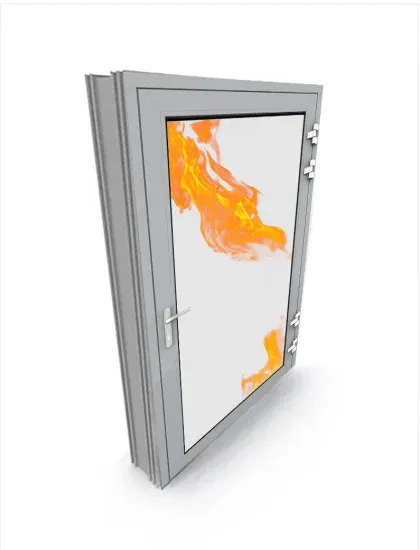

Toughened glass, also referred to as tempered glass, is manufactured through a controlled toughening process that involves heating standard float glass to high temperatures before rapidly cooling it. This process induces internal stresses across the surface, giving the glass a high breaking point. In the event of breakage, the glass fragments into small, blunt pieces, mitigating injury risks associated with immediate sharpness. This property makes it particularly suitable for doors, partitions, balustrades, and other architectural applications where user safety is paramount.

Modern fabrication techniques allow custom toughened glass to be produced with drill holes, socket cut outs, radius corners, and dubbed corners, accommodating complex designs without compromising performance. Attention to hole size and the minimum drill hole size is essential to avoid stress concentration and potential glass shattering.

Laminated glass as a high-retention safety solution for modern glazing

In contrast, laminated glass is composed of two or more layers of glass bonded together with a durable interlayer material. If the pane is struck or cracked, the interlayer holds fragments in place, preventing them from falling and thereby maintaining structural integrity. This characteristic is particularly beneficial for overhead canopies, glass roofing, or high-level glazing where falling shards would present a serious hazard. Laminated variants, often referred to as laminated safety glass, also provide enhanced resistance to impact and ultraviolet light, preserving interior finishes from fading.

When specifying laminated units, designers and installers must consider laminated glass quantity and consult specialists to ensure that the exact requirements are met. In bespoke projects, precision technical drawings and attention to desired dimensions ensure that the panels integrate seamlessly with other architectural elements.

How glass thickness shapes the performance of toughened and laminated safety glass?

The selection of glass thickness is a decisive factor in determining the structural and safety performance of both toughened and laminated units. For instance, larger glass panels or balustrades require thicker laminated sheets to resist bending and maintain load-bearing capacity, while toughened glass may achieve similar strength at slightly reduced thickness due to the tempering process. Careful calculation ensures that the glass thickness chosen is appropriate for wind loads, spans, and intended use. In furniture applications such as table tops or glass shelves, selecting the correct thickness is essential to prevent deflection or failure under regular use.

From float glass to toughened or laminated safety units: understanding the manufacturing route

Float glass serves as the fundamental raw material for both toughened and laminated glass. Produced by floating molten glass on a bed of molten tin, this process yields panels with uniform thickness and minimal optical distortion. Once fabricated, float glass may either be toughened through tempering or laminated with an interlayer material, depending on the intended application. While clear float glass offers excellent transparency for decorative purposes, it does not meet the safety glass requirements that are often essential in modern residential or commercial buildings.

Why is glass cut to size critical when choosing between toughened and laminated glass?

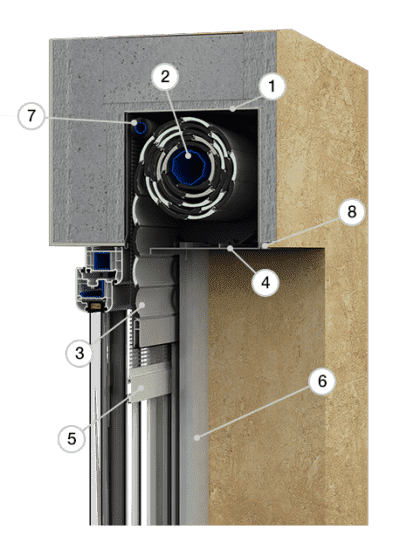

Many contemporary glazing projects require glass cut to size to fit specific architectural configurations. With toughened glass, toughened glass cut must be performed before the tempering process, as post-tempering cutting can compromise structural integrity. Laminated glass, on the other hand, allows for certain modifications after bonding, although care must be taken to maintain edge quality and avoid delamination. Considerations such as socket cut outs, drill holes, and internal radius adjustments must be precisely calculated. Using tools like a dimensions calculator ensures that each panel meets design expectations while avoiding stress points that could lead to failure.

The importance of polished edges in ensuring safe installation of toughened and laminated glass

Proper edge treatment is essential for safety and durability. Polished edges reduce the risk of injury during handling and installation, while also preventing chips that could compromise strength. In glass shelves, stair treads, and other exposed installations, a polished finish combined with rounded corner or corner rectangle adjustments significantly improves safety and longevity. Both toughened and laminated panels benefit from these treatments, although laminated sheets retain fragments even if edges are damaged, offering an additional layer of protection.

Clear toughened glass versus standard clear glass in safety-critical glazing

While clear glass offers excellent transparency, it often does not meet regulatory standards for safety-critical applications. Clear toughened glass provides enhanced impact resistance and a defined breaking point, making it the preferred option for doors, partitions, and balustrades where user safety is paramount. Its optical properties closely match clear float glass, ensuring that transparency and aesthetic quality are preserved while meeting safety glass requirements.

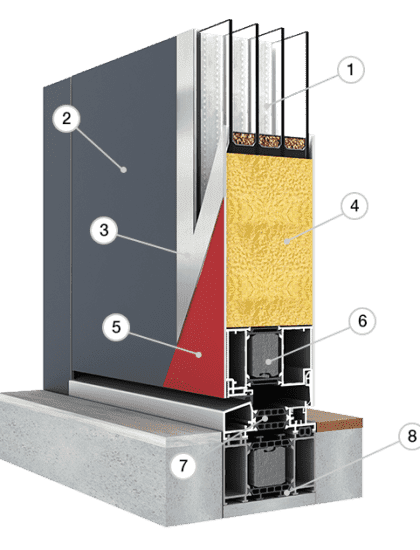

Designing safe and stable glass panels using toughened or laminated glass

Large glass panels require careful planning to maintain stability and performance. Toughened glass provides uniform strength, whereas laminated units offer superior retention in case of damage. When specifying panels, designers must consider internal notches, socket cut outs, and radius corners, as well as the implications of same thickness layers and hand rake or double rake adjustments for sloped installations. Ensuring structural integrity and correct installation methods reduces the risk of breakage and extends the lifespan of the glazing.

The role of both glass types in modern glazing practice

Both toughened and laminated glass are reliable choices when selected according to the intended application. Each type offers distinct advantages: toughened glass is excellent for impact resistance and applications where controlled fragmentation is desirable, while laminated glass provides retention of fragments and superior security. In all cases, DAKO applies rigorous standards and uses safe, tested solutions to ensure that installations comply with British building regulations. By choosing the appropriate type of safety glass, designers and homeowners can achieve both aesthetic appeal and long-term safety without compromising quality.