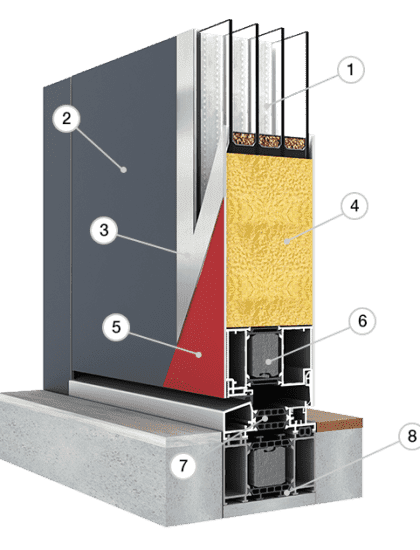

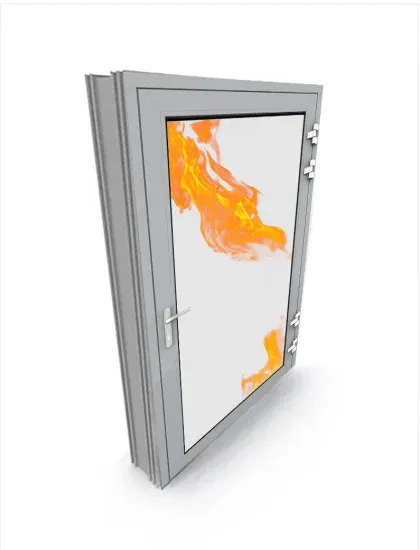

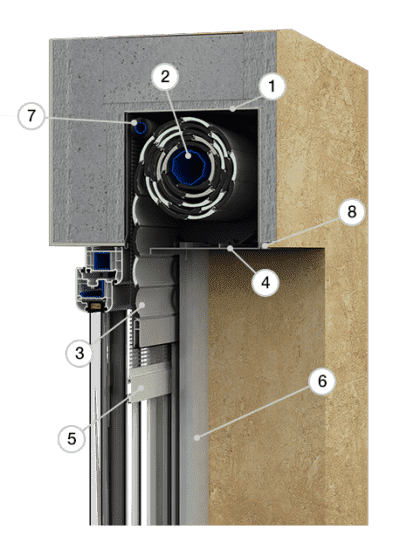

How do we protect our products against the harmful effects of external factors

In order for DAKO products to serve our customers as long as possible, we pay special attention to providing them with adequate protection against adverse weather conditions.