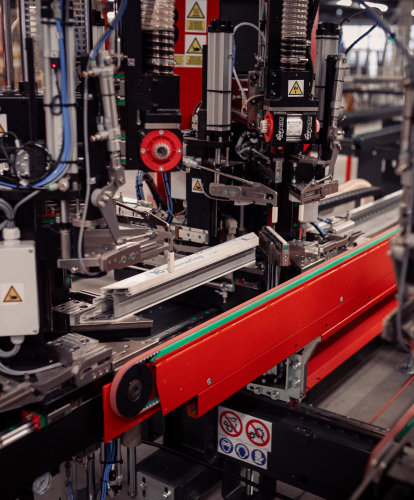

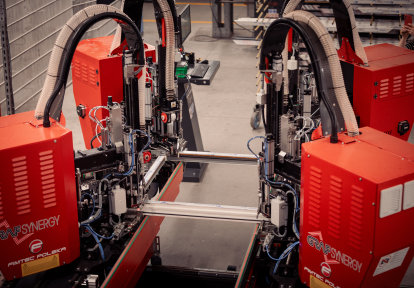

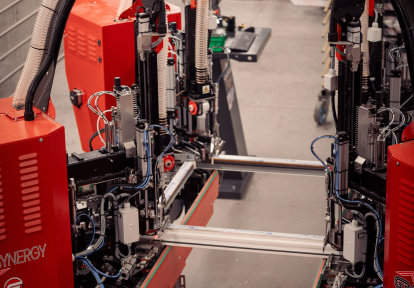

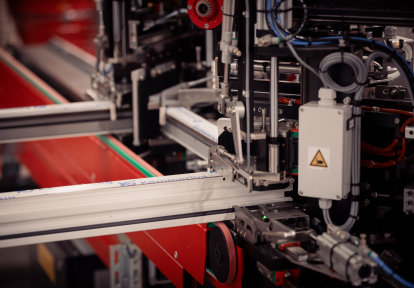

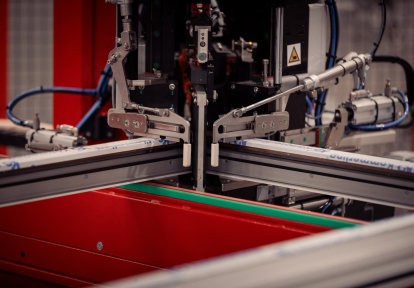

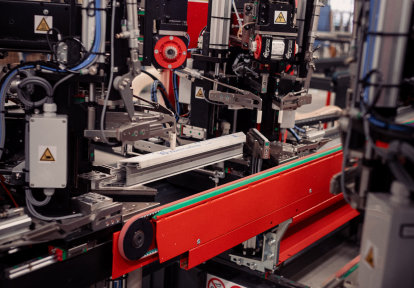

DAKO consistently adopts innovative technologies to deliver the highest quality joinery to customers around the world. Lately, a new welding robot, the SL4 FF EVO RS, supplied by Fimtec Polska, has arrived on the PVC manufacturing floor. The machine will significantly improve the production processes of PVC joinery and further improve the precision of welding.

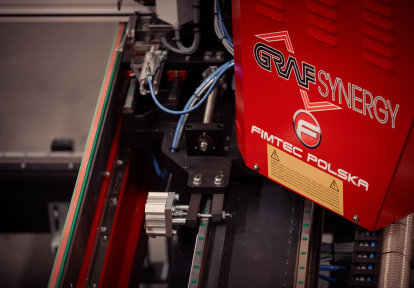

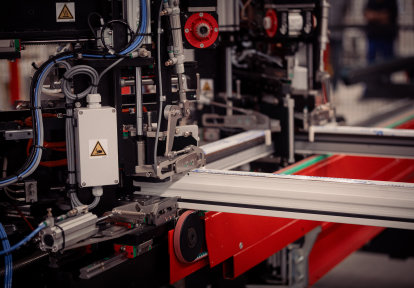

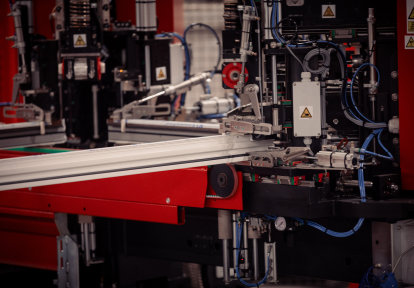

Strategic investments and upgrading the machinery stock have been important elements of DAKO’s technological development for years. As part of the latest expansion of the machine park, the innovative welding robot SL4 FF EVO RS, manufactured by Italian supplier Graf Synergy S.r.l., was installed in the PVC joinery shop.

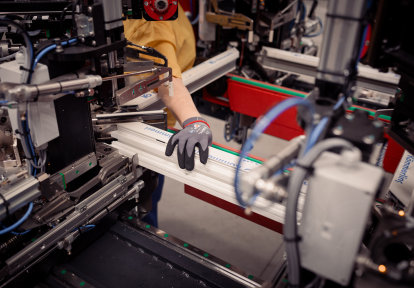

The machine was delivered and installed by specialists from Fimtec Polska – a long-standing DAKO contractor. Powered by V-Perfect technology, the robot achieves flawlessly finished flash-free weld while maintaining the strength of the profile joints and high productivity.

– “By implementing robotics on the production halls, we are constantly raising our standards, responding to the market demand for new generations of products: energy-efficient windows and doors in line with design trends, and with the highest technical performance. The newly acquired SL4 FF EVO RS robot will improve the production processes of PVC joinery, which has remained the top choice among our customers for years. As production manager, I greatly appreciate the partnership with Fimtec, which has supported us for years with the technical expertise of its specialists and top-quality machinery.”

Michał Kantor

Production Manager PVC Joinery

Our collaboration with Fimtec Polska has been going on for years, allowing us to flexibly adapt technological solutions to the ever-changing needs of global markets. Notably, there are more machines provided by the company in the DAKO shop floors, including machining and cutting centres and other welding robots.

– “Our long-standing partnership with DAKO has allowed us to better understand our customer’s needs and adapt our technologies to challenging market conditions. This enables us to provide solutions that streamline manufacturing and increase efficiency. At present, DAKO’s machine park is equipped with two SL4 FF EVO machines and the latest EVO RS robot, as well as three high-performance machining and cutting centres combined with an automatic ASG station. Each machine has been custom configured to ensure maximum precision and optimisation of production processes. Worth noting is the fact that EVO RS is already the more than 1,000th GRAF Synergy welding robot, demonstrating the ongoing development of this technology and its importance in the production of top-quality windows.”

Grzegorz Ulkowski

Technical and Sales Consultant, Fimtec Polska

Fimtec Polska representatives also recently visited the DAKO production and office centre in Nowy Sącz to see the new machine in action and discuss the next stages of the partnership. The visitors also had the opportunity to see DAKO’s showroom of nearly 1,000 m2, which impressed them with its modernity and extensive product display.