The heat engine analogy: how windows act as barriers to heat flow

To understand window performance, one might compare it to the workings of a heat engine. In mechanical systems, heat energy moves from a hot reservoir to a cold reservoir, doing useful work along the way — a process governed by the laws of thermodynamics. While a window isn’t a machine that generates mechanical energy, it does serve as a medium through which thermal energy can be lost or retained, depending on its construction and quality.

The analogy highlights how the combustion process in an internal combustion engine creates energy, while windows must be designed to prevent heat loss during winter and block external heat during summer. Products such as DAKO’s triple-glazed windows minimize heat transfer, acting as passive energy-saving solutions that complement energy conversion processes within the home. The effectiveness of such windows depends on the materials used and the engine design of the window profile — elements that manufacturers like DAKO continue to optimize through innovation and testing.

Energy efficiency at home: the role of thermal window characteristics

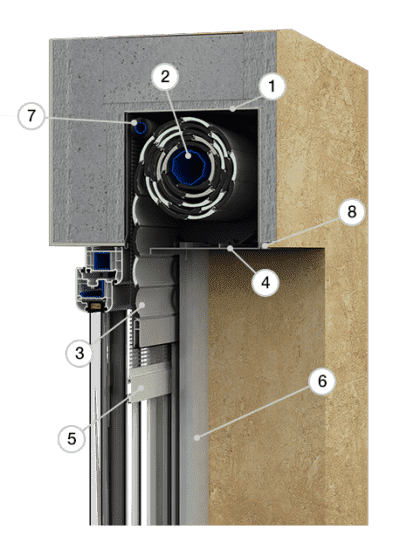

The energy efficiency of a building greatly depends on its envelope — including its windows. Windows characteristics such as the number of panes, spacer bars, gas fills (e.g. argon), and frame materials play key roles in determining heat input, heat loss, and overall thermal efficiency. In climates with considerable temperature difference between seasons, minimising heat transfer through windows helps reduce demand on HVAC systems, directly influencing fuel efficiency and power output at the household level.

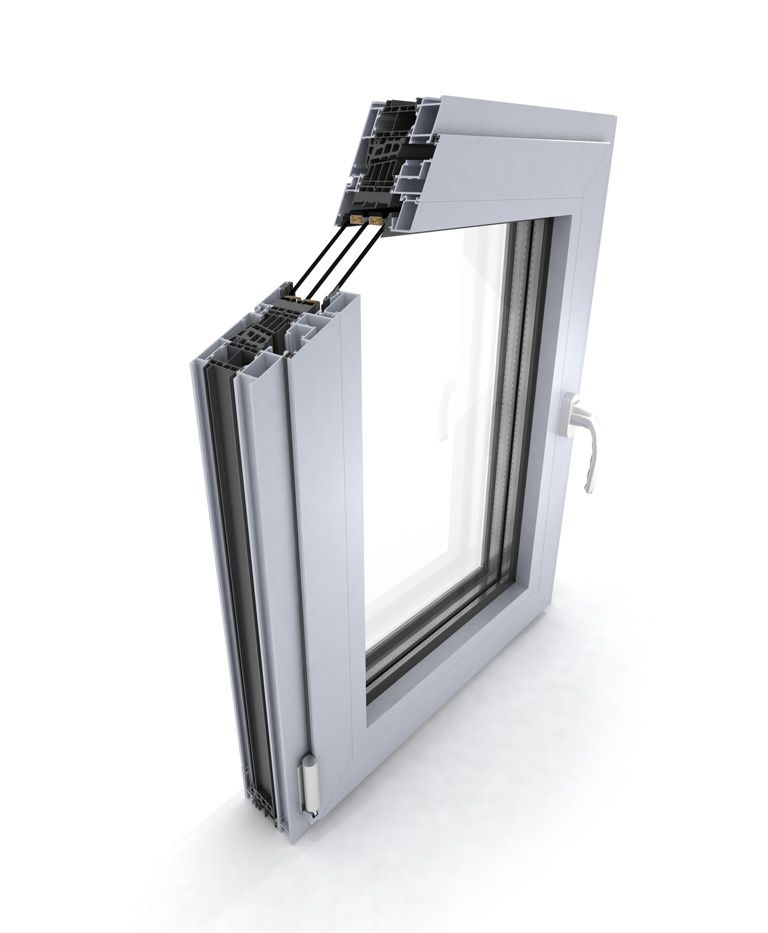

DAKO’s DPQ-82 system stands out in the PVC category with its multi-chamber profile and triple-sealed sash, which work together to limit thermal energy loss. Its low Uw-value rating positions it among top-performing solutions in its class, meeting the growing demand for energy conversion optimization. In combination with high-performance glass, such windows prevent heat loss and improve the mechanical efficiency of a home’s thermal system. DAKO’s ongoing R&D ensures that these windows characteristics remain aligned with European standards and consumer expectations.

Carnot efficiency and the quest for maximum thermal performance

The concept of Carnot efficiency, derived from thermodynamics, represents the maximum possible efficiency any heat engine can achieve based on the temperature difference between the hot and cold reservoirs. While a window doesn’t generate mechanical energy, it certainly interacts with thermal energy flow between indoor and outdoor environments. In this analogy, the house is the system, and windows help maintain internal conditions despite external fluctuations.

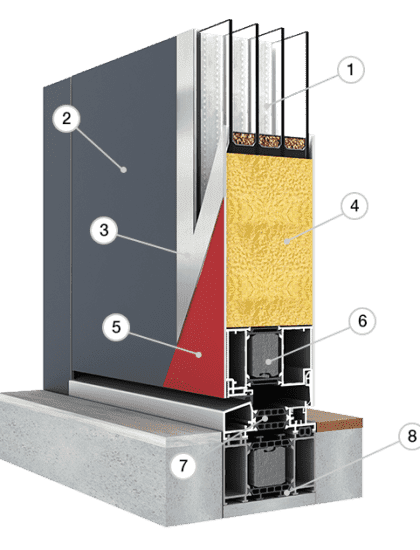

By using technologies inspired by the Carnot cycle, such as thermal breaks and multi-glazing units, DAKO windows significantly reduce heat transfer. This approach mirrors the effort in combustion engines to minimise waste heat and increase brake thermal efficiency. For example, the DA-77 aluminium window system combines thermally broken aluminium profiles with advanced glazing to achieve higher thermal efficiency, offering optimal insulation with slim, modern frames. These products not only reduce energy usage but also support broader energy efficiency goals for homes and commercial buildings alike.

Compression ratio in window construction: maximising energy retention

In internal combustion engines, the compression ratio is a measure of how effectively an engine compresses the fuel air mixture—a critical factor in determining thermal efficiency. In the realm of windows, the “compression” can be likened to the tightness of the seal, the quality of materials, and the window’s capacity to resist airflow and temperature exchange.

DAKO’s windows are engineered to optimize this metaphorical compression. Features such as multi-point locking systems and flexible weather seals work together to retain thermal energy and reduce heat loss. This ensures comfort even during harsh winters in the UK or Ireland, where ambient temperature changes can be severe. Much like an internal combustion engine benefits from higher compression ratios, homes fitted with DAKO’s advanced window systems enjoy improved energy output and overall thermal performance.

Heat exchanger logic in window design

A heat exchanger allows heat energy to pass from one medium to another without direct contact. Similarly, windows must manage thermal energy while keeping interior and exterior environments physically separated. DAKO windows—especially those with low-emissivity coatings and argon-filled glass units—act like efficient heat exchangers, preventing valuable heat energy from escaping while letting in natural light.

The DA-77 aluminium system, for instance, uses thermal breaks that reduce heat transfer through the frame while maximising daylight entry. This synergy of light and insulation improves both energy efficiency and interior comfort. Homeowners benefit not only from a more consistent indoor temperature but also from reduced reliance on heating systems—translating into lower energy bills and less environmental impact. The windows characteristics seen here support DAKO’s commitment to maximum efficiency and sustainable design.

Steam engines and the evolution of thermal technologies in windows

The historical transition from early steam engines to today’s internal combustion and heat engines illustrates the human pursuit of improved thermal efficiency. Similarly, window technologies have evolved from single-pane wood frames to sophisticated multi-layered systems that rival the complexity of industrial equipment in their thermal performance.

Just as a steam turbine converts heat energy into mechanical energy, modern windows convert materials and construction techniques into thermal energy retention tools. With innovations like laminated glazing, warm edge spacers, and thermally efficient profiles, DAKO’s offerings reflect this evolution. These products—such as those in the DPQ-82 PVC range—minimise waste heat and ensure that homes retain as much internal energy as possible during colder months. The technological progression from steam engines to passive energy systems in building components underscores the growing importance of smart energy conversion in architecture.

Internal energy and the role of windows in energy retention

In thermodynamics, internal energy refers to the total energy contained within a system, including kinetic and potential energy at the molecular level. For buildings, this internal energy manifests as the warmth we feel indoors. Maintaining that energy becomes especially important during colder months in the UK and Ireland, where heat loss can significantly raise energy consumption.

DAKO windows are designed to preserve internal energy by minimising heat transfer through the use of multi-chambered profiles, specialised sealing systems, and high-quality glazing. For example, the DPQ-82 PVC window system offers excellent insulation properties that help retain warmth inside the house, even as the ambient temperature outside drops. This ensures that thermal energy remains inside the building, reducing the need for heating and improving energy efficiency.

Power plants, carnot heat engines, and domestic window technology

Just like power plants strive to convert fuel into electrical energy as efficiently as possible, windows must control the flow of thermal energy to maximise comfort and reduce energy waste. While a carnot heat engine represents the theoretical pinnacle of thermal efficiency, real-world systems—including window installations—aim to come as close as possible to this ideal.

DAKO approaches this challenge with engineering precision. Both the DA-77 aluminium windows and DPQ-82 PVC windows use advanced materials and production techniques to reduce heat input from the outside in summer and minimise heat loss in winter. This bi-directional control helps buildings function more like closed systems—much like reversible engines used in some industrial settings. The result is improved energy conversion in the form of better thermal regulation and reduced operational costs for building owners.

Understanding heat loss and the importance of window design

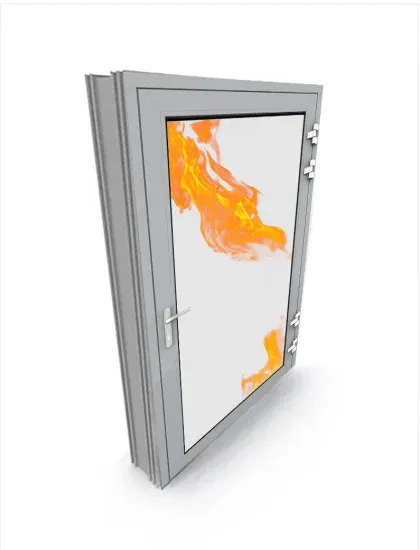

Heat loss through windows typically occurs via conduction, convection, and radiation. Poorly insulated windows become a pathway for waste energy, allowing all the heat generated inside to dissipate. This not only affects indoor comfort but also drives up utility bills and undermines the building’s energy efficiency.

DAKO mitigates this risk by employing low-emissivity glass, multi-glazing, and specialised spacers to reduce heat transfer. The windows characteristics of products in the DA-77 and DPQ-82 ranges are engineered to keep heat inside, particularly during colder months common in Ireland and the UK. These solutions are effective even under tough temperature limits, providing comfort without overreliance on mechanical heating systems. That’s why DAKO windows form a key part of any high-performance energy strategy for modern buildings.

Reversible engines and the analogy to energy efficient windows

Reversible engines in thermodynamic theory are idealised systems that can operate forwards and backwards with no loss in energy. While no real engine can achieve this, the concept encourages innovation in maximising output with minimal input. The same philosophy applies to the design of DAKO windows: they aim to allow beneficial energy exchange (e.g. natural light) while preventing unwanted energy flow (e.g. waste heat).

Windows in the DAKO product range mirror this efficiency by being selectively permeable—letting in light and controlling thermal transfer with pinpoint accuracy. Advanced combustion engines seek to increase mechanical efficiency, and DAKO windows follow suit by optimising thermal energy retention through cutting-edge engineering and material science. This results in better comfort, lower energy bills, and more sustainable homes and workplaces.

Constant pressure, latent heat and why window systems must handle more than Uw-values

Just like combustion engines operate under constant pressure during certain stages of their engine cycle, buildings experience continuous pressure from environmental factors—temperature fluctuations, wind, and moisture. A well-engineered window must not only block direct heat transfer but also manage internal condensation, vapour pressure, and latent heat changes, especially in climates like the UK and Ireland, where humidity is often high.

DAKO windows are constructed with advanced ventilation options and multiple seal systems that function well even under difficult atmospheric conditions. The inclusion of warm-edge spacers and triple glazing in systems like the DPQ-82 and DA-77 helps regulate latent heat changes, minimising interior condensation and supporting overall thermal efficiency. In thermodynamic terms, the system behaves like an advanced heat exchanger, reducing energy loss even when external conditions are dynamic.

Fuel efficiency and engine design as a mirror for window innovation

Just as improved engine design enhances fuel efficiency, advanced window manufacturing improves energy performance in buildings. Higher compression ratios in diesel engines and gasoline engines yield better thermal efficiency, and similarly, better-designed window chambers and insulating layers deliver lower Uw-values. These architectural solutions take cues from the same physical laws that govern thermodynamic efficiency in engines.

DAKO’s manufacturing process involves precise control over materials and design. With a focus on sustainability and performance, DAKO has refined its windows characteristics to enhance fuel air mixture resistance—limiting heat exchange just as combustion chambers limit external energy loss. These measures ultimately contribute to significant energy savings for homeowners and businesses across Ireland, the UK, and beyond.

Air fuel, combustion process and the drive for sustainability

Within combustion engines, the air fuel ratio must be tightly controlled to achieve ideal combustion temperature and avoid excessive waste heat. The combustion process must be optimised to ensure maximum energy output with minimal input. Similarly, DAKO optimises its thermal efficiency through window systems that act like a fine-tuned barrier—filtering out undesirable temperature transfer and maintaining internal stability.

Windows such as the DA-77 aluminium system and DPQ-82 PVC system are developed with a performance-first mindset. Their internal chambers act similarly to combustion chambers, efficiently managing incoming and outgoing thermal energy. In this way, DAKO brings the engineering principles of power plants, heat engines, and thermodynamic cycles into the everyday spaces of homes and offices.

The real-world impact of high thermal efficiency windows

Understanding thermal efficiency isn't just about textbook formulas like Carnot efficiency or brake thermal efficiency—it’s about practical, measurable improvements in how our buildings consume and conserve heat energy. With climate targets becoming stricter and energy prices rising, the role of highly efficient windows is now more critical than ever.

DAKO’s dedication to maximum thermal efficiency through its DA-77 aluminium and DPQ-82 PVC windows proves that combining thermodynamic theory with advanced engineering can produce superior building solutions. These windows don't just meet the modern expectations of thermal efficiency, energy efficiency, and durability—they embody them, bringing industrial principles into elegant architectural forms tailored to the needs of the UK, Ireland, and the wider European market.